MAHLE/KNECHT Technical information: Filter leakage

DESCRIPTION

There is a sudden loss of liquid or poor performance of the vehicle. Moreover, partial wear is detectable at the engine. Besides the normal leakage at the connection, the following leaks occur:

- Fuel spin-on filter (KC): At the filter housing, there is a longitudinal or transverse crack at the transition radius.

- Inline fuel filter (KL): Either the filter housing is corroded or there is partial corrosion at the line connection due to a damaged fuel hose, resulting in water between the hose and the connecting piece.

- Oil spin-on filter (OC):

– The filter housing has been cracked (Fig. 1), swollen (Fig. 2) and/or the o-ring housing has been pushed out (Fig. 3) and/or cracked.

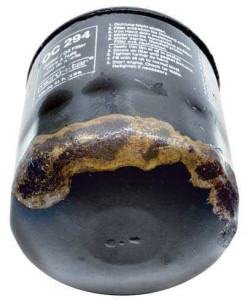

– There is corrosion (Fig. 4).

PROBABLE CAUSES

Fuel spin-on filter (KC):

The cause of the crack at the transition radius is dynamic load (Fig. 1), e.g. if the fuel spin-on filter has been installed incorrectly, it cannot withstand the dynamic pressure load.

If the filter connection is leaky, the following assembly errors may be the cause:

- The filter has been installed in a slanted position (Fig. 5).

- The o-ring is fitted incorrectly.

- An old o-ring has been re-used.

- The tightening torque was incorrect when installing the filter.

Inline fuel filter (KL):

- With aluminum housings, contact corrosion between the aluminum and the retaining clamp of the filter can occur due to the protective filter film being removed or damaged (Fig. 6), resulting in the filter being leaky.

- Corrosion or leakage at the line connection can occur due to the

following assembly errors:

– The o-ring is porous, has not been replaced or slipped during assembly.

– The hoses are not correctly connected to the fittings.

– The hose clamps are tightened insufficiently.

Oil spin-on filter (OC):

- The filter housing is cracked or swollen or the o-ring has been pressed out or torn due to the following reasons:

– The pressure limiting valve in the oil pump is defective.

– An oil filter which has not been approved for the engine has been used (incorrect application). - The filter has not been tightened correctly.

- Oil filter leakage can be attributed to the following assembly errors:

– The filter has been installed in a slanted position.

– The o-ring is fitted incorrectly.

– The tightening torque was incorrect when installing the filter. - Corrosion at oil spin-on filters can have the following causes:

– The time between change intervals is too long.

– The filter has not been tightened by hand but with a special extraction tool. And the corrosion protection has been damaged.

REMEDY/PREVENTION

- Always adhere to the change intervals.

- Only use filters recommended for the engine.

- Do not use a special extraction tool to tighten the filter.

- Always use new seals (o-rings, copper-aluminum washers).

- If considered necessary, it is advisable to replace the pressure limiting valve of the oil pump.

- Always adhere to the assembly instructions.

Komentari

Još nema komentara